Gravity Die Casting Applications

Ming Ming Aluminium Co., Ltd. adopts an automatic tilting gravity casting procedure, which ensures the production of high-grade aluminium cast components. We have provided aluminium alloy solutions to various industries, including machinery, automotive, motorcycle and e-bike, medical devices, and food machinery, around the world.

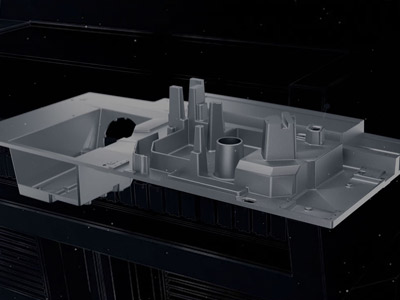

Compared with aluminium forgings, our e-bike aluminium gravity casting parts need only simple turning before being used in the e-bike production. This results in efficient and cost-effective pre-production process and the production speed of e-bikes could be improved.

The motorcycle aluminium gravity casting parts we manufacture meet the strict requirement and highly demanding standards for the global motorcycle market. Our automobile applications are exported to Japan and trusted by our clients.

We also manufacture parts of robotic arms that have a smooth surface and would not damage the wires in repetitive motions. And our aluminum casting parts for pneumatic and hydraulic tools are lightweight, high tensile, of quick heat dissipation, and with compression strength reaching 210kg/cm².

Ming Ming’s gravity casting also serves manufacturers from other industries which need components of high precision for their machines.

Click the following items to get more information.

Lightweight e-bikes parts, which can be forged with other components by welding and make the production of e-bikes efficient and cost-effective.

Impact-resistant, airtight, and stylish casting motorcycle parts meet the strict requirement and highly demanding standards for the global motorcycle market.

Customised automotive parts, which are heat and corrosion resistant and have excellent damping capacity. Our high-precision casting automotive parts are trusted by the Japanese manufacturers.

Ming Ming’s parts for robotic arms have a smooth surface and would not damage the wires in repetitive motions.